|

_Our

two-day rudder workshops are modeled after Zenith Aicraft's successful

factory workshops of the same name. These popular workshops have been

offered for over twenty years with hundreds of graduates coming from

around the world. The workshops are designed to give would-be builders a

taste for kit assembly, before commiting to a complete kit. Some

builders, having already made up their mind, arrange to pick up their

kit during the workshop; it's a great way of getting a head-start on a

kit plane project...

Following is one participan't experience, shared through his local EAA chapter newsletter upon returning home. ****************************************************************************************************************************************************************** ****************************************************************************************************************************************************************** |

_After attending a Zenith Aircraft workshop in Cloverdale California, I

can honestly say I had one of the best weekends in long time. At the

workshop you build a complete rudder for a Zenith CH 650 or CH 701. The

workshop was conducted by Quality Sport Planes (QSP) and took place in

their hangar at the Cloverdale airfield. A bonus to attending this

particular workshop was an open house and fly in. That meant over a

dozen Zenith kit planes for me to look at and pilots to talk with.

|

_The decision to go has it roots in my long search trying to decide what

airplane to build. I have researched numerous models for the following

features: LSA, easy to build, good visibility, safe/easy to fly, and

within my budget. I have bought blueprints for single seat, two seat,

parasol, biplane, high wing, shoulder wing, and folding wing planes. For

one reason or another I have eliminated all of the designs. The list of

reasons is long: too complicated, terrible plans, no builder community,

poor engine selection, too hard to fly and on and on. The real killer

seems to be indecisiveness, as a few of my chapter friends can testify.

‘So what plane do you plan to build this month?’ they have asked. My

loving and obliging wife has endured many sessions of ‘what do you think

of this plane’. My daughter, almost 3, can now identify a biplane when

she sees one.

|

_I jokingly refer to my latest building idea as my ‘Plane

of the month’. I have even attended an EAA workshop aimed at entry level

skills to help you decide what kind of construction technique might

appeal to you. Tube and rag or all wood planes looked the most

attractive. Composite construction was too messy and hazmat filled.

Aluminum construction was okay, though I really disliked bucking rivets

with the noisy air hammer.

|

Choosing to build a rudder for the aluminum CH 701 kit plane seemed out of character for me. The CH701 meets my requirements, so why not try it. However, the choice to go to this workshop was mostly centered on the fact I could start to build something without a large outlay of cash. I could see if all this dreaming about building a plane had any substance. I have known about the Zenith workshops and was under the impression I had to travel to the factory site in Missouri. I was thrilled to discover that QSP in Cloverdale, run by Michael Heintz, also offered the workshops. I sent off the deposit for the workshop and received a response saying I could bring another person along to help me. So I enlisted another chapter member, Randolph Skrovan, who happily accepted. On Friday, after the kids had been put to bed, Randolph and I took off for Cloverdale by car. I did not want to risk a VFR plane trip with my non-instrument rating, being bound by the workshops start and end times. I also had to bring home a finished rudder and wasn’t sure it would fit in the plane. As it turns out, traveling by car was a good choice; the fog would have kept us out of WVI on Sunday evening. I think the rudder would have fit in the plane easily. _ |

|

_

The Cloverdale airport is right next to Hwy 101, and gives the sense of a wonderful, cozy rural airport, with QSP’s hangar being the largest on the field. Randolph and I were right on time and among the first to arrive. A busy QSP staff were setting up for their open house. So we chipped in with the set up and took some time to have some coffee and doughnuts. After a short while the rudder workshop attendees arrived and introduced themselves. There were three CH701 rudders being built and one CH601 rudder. Everyone else had predetermined what they wanted to build. Michael Heintz started off by explaining their philosophy of the workshop: to get us to the point where we would need little help working from the plans and instruction manual. So Michael and his workshop staff, Erik Peterson and Doug Dugger, would be available for any questions but weren’t going to hover. |

|

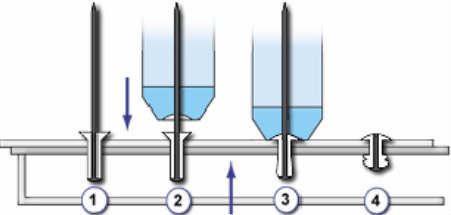

_Pulling rivets, as compared to bucking rivets, entails loading up the

pneumatic rivet gun with a rivet, pushing the rivet through the hole,

squaring up the gun with the mating surfaces and squeezing the trigger. I

wasn’t prepared for the satisfaction that resulted from squeezing the

rivet gun’s trigger. The gun makes a sound sort of like: Whoosh – bink! I

smiled and did another one. Whoosh-bink. I looked over at Randolph and

said “ Oohhh, you gotta do this! This is great!”. This was nothing like

solid rivet bucking I had previously done. This was fun! The riveting

alone provides an incentive to do all the other previous steps. I made

sure Randolph and I split up the riveting between us, as it was so much

fun.

I also discovered that it is easier to drill out badly set pulled rivets compared to solid rivets (which only happened once, I am proud to say). Punch out the steel pull pin with a modified center punch. Drill the rivet to the hole size. The head falls off. Push out the remaining part of the rivet. Piece of cake! |

_Since the work shop was concurrent with QSP’s open house, we got

distracted and listened in on a few forums on flying the CH701. I also

spent a lot of time sitting in both a CH701 and CH601. I was surprised

to see there wasn’t a lot of headroom in the CH701. After reading the

Zenith literature, I had expected more headroom, but not too surprised

as this problem is common for me in just about all vehicles. As it turns

out Michael Heintz is also tall, and they had modified their soon-to-be

flying demo CH701 by lowering one of the seat pans. I found I had

headroom in that seat, a bit upright, yet comfortable. However the

lowered seat felt a little more like sitting in a bucket, literally. I

found the visibility excellent in all directions but straight back. I

especially liked the fact that I could look out the side window without

having to bend over to get my eyes under the wing. In contrast, when I

sat in the CH 601, I was stunned by its’ comfort. Perhaps the most

comfortable plane I have ever sat in. I also discovered I sat pretty low

compared to the top of the canopy bubble. I could easily imagine the

runway disappearing in a landing flare, though I had taken some of the

cushion out of my seat to make sure the canopy didn’t hit my head.

|

_With all the distractions of the open house, the BBQ, and running into

other Chapter 119 members (Dennis and Jerry) who flew up for the day, we

didn’t progress very far on my rudder. By the end of the day, all we

had accomplished was attaching the ribs to the spar. The next morning we

got an early start. The QSP staff was hovering a little closer, so less

time was spent wondering what to do when stumped by a procedure.

|

_Putting the skins on was an exciting and nerve racking experience. I

kept hoping we lined up the ribs correctly. We made some errors, all

recoverable. We also learned some skills and tricks you could only learn

from someone who knew them, well worth the price of the workshop alone.

Perhaps the most valuable thing I learned in the workshop was how

precise I needed to be. Initially I was trying to be extremely precise: I

wasted a lot time for not much gain. Then I tried being a bit more

relaxed on my tolerances and provided myself with some sloppy

workmanship that was noticeable, but not deficient. Eventually we

settled into an ability to work with a bit of speed, not be unduly

precise, and still have good workmanship.

|

_True to the advertisement, we had finished our rudder by 3pm Sunday. We

had been secretly racing the other workshop attendees, but the guy with

the CH601 Rudder beat us in the end. We were surprised as we didn’t see

him around very much. All the CH601 rudder skins come pre-drilled,

something only the fuselage and wing skins have on the CH701 at the

moment. Still, given our easily distracted work effort, I was impressed

how easily and quickly the rudder came together.

The question still remains whether or not the CH701 is the plane. I had planned to take a demo ride in the CH601, but that was cut out of the plans as we wanted to get home to relieve our wives of watching the kids. Michael Heintz promised me that when QSP’s CH701 demo plane was done, we could come back for a test ride, and fly both models during the same visit. Either way I had fun at the workshop and continue to enjoy my slow process towards building a plane. As I do recall, this plane building is suppose to be fun! |

For more details on QSP's rudder workshop, including dates, click HERE!